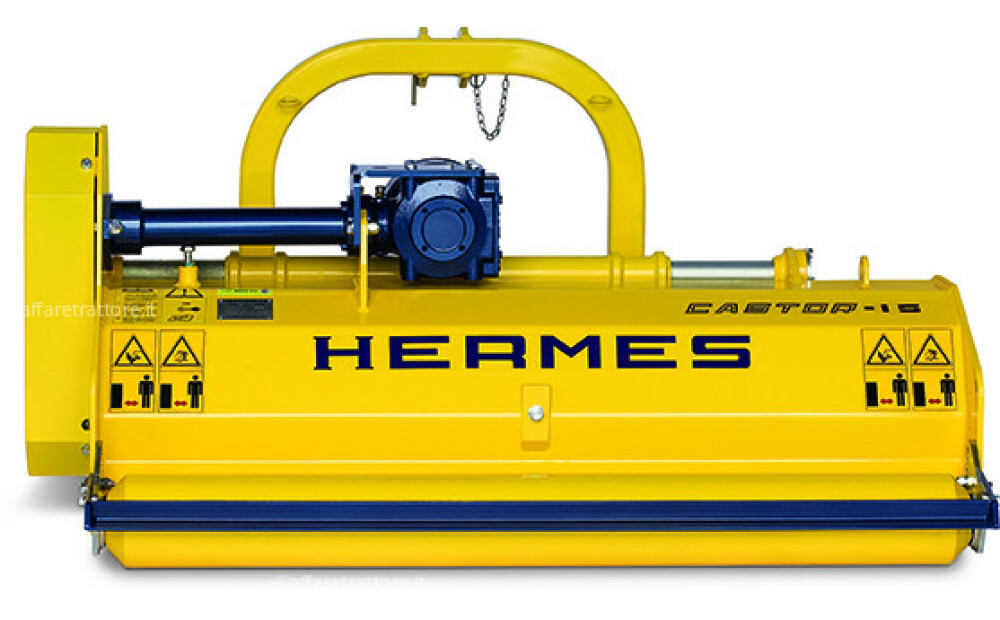

Defining the Castor simply as a shredder would be limiting. It is a machine born from careful design by our technicians. The task entrusted to them is to develop and build robust and high-quality machines. By fully fulfilling this task, the Castor was born, a machine that meets the needs of modern farmers.

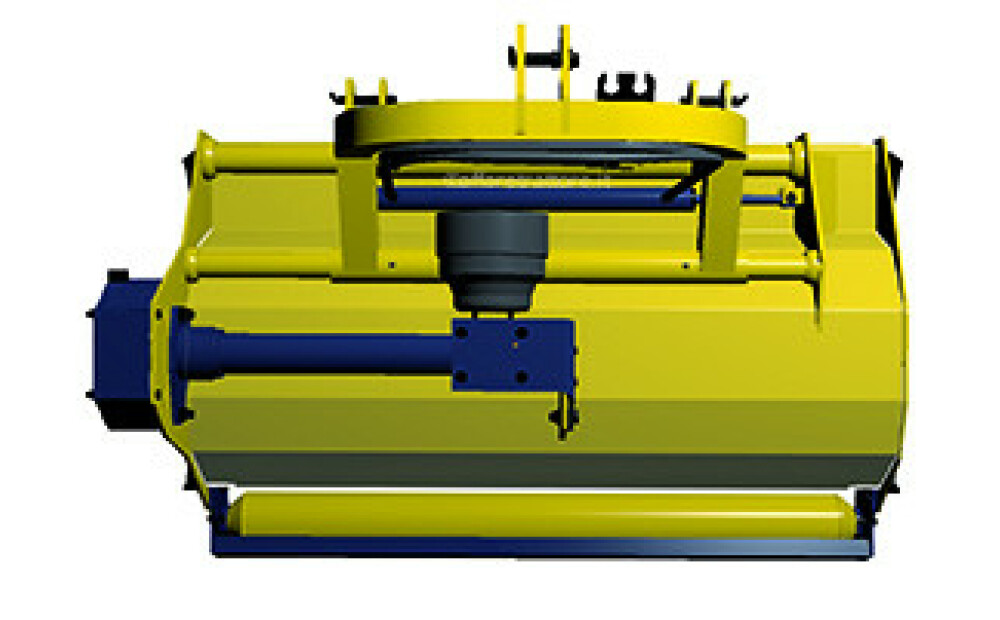

To create the Castor, Hermes uses the most modern production processes: from the selection of raw materials, to the use of the most modern high-precision CNC machinery and the computerized electronic balancing of the hammer-holder rotors. All these processes are carried out within Hermes and the control of each process is performed by our company's technicians. In this way, we differentiate ourselves from many other companies that use outsourcing for production, thus limiting themselves to assembling purchased components.

To build an exceptional machine, high-quality components are necessary. Hermes technicians put this experience into practice every day, carefully selecting each component. Only the careful and meticulous control of the components and processes allows us to build the Castor so that it perfectly meets the demand for robustness and durability.

Innovation is a fundamental element for our technicians. Always attentive to the changes and changing needs of farmers, Hermes continues to improve and adapt its machines: in addition to the continuous research of production processes aimed at improving the performance of the Castor, we offer a range of cutting, options and versions such that it is possible to adapt our machines to every need.

Innovation, quality, reliability, robustness explain why we are proud of our Castor.

Via Roma, 6, 39010 Gargazzone BZ, Italia