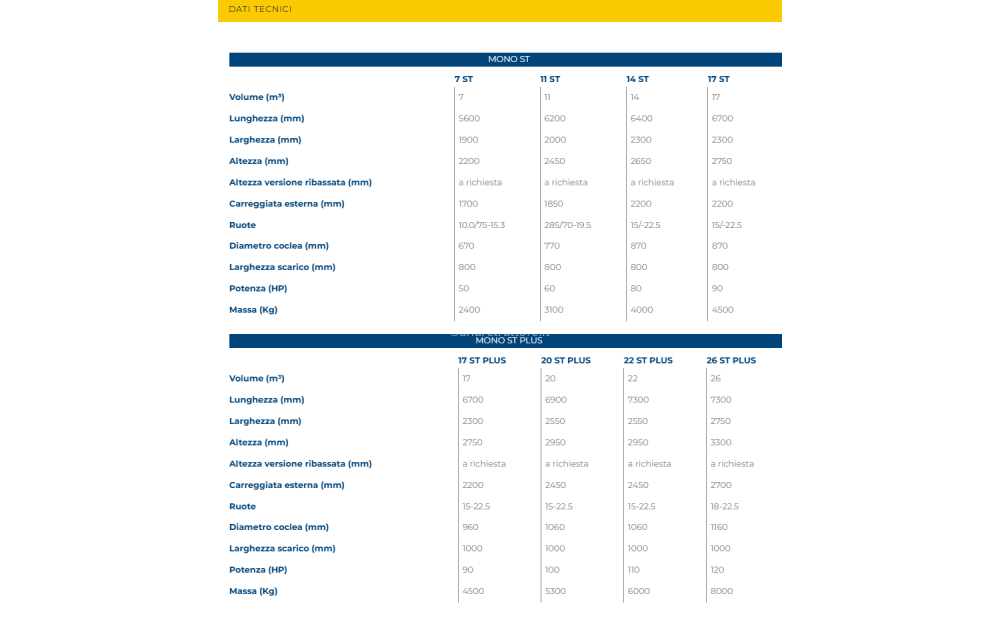

TRAILED HORIZONTAL SINGLE AUGER – FROM 7 TO 26 M³

Strengthened by the effective and well-tested Monofeeder technology, the ST model stands out for the simplicity of its components and mechanical parts, as well as for its high reliability. Essential prerogatives that make the Monofeeder one of the best-selling and most appreciated horizontal machines on the market.

THE MACHINE CAN ALSO BE MADE IN A STATIONARY VERSION POWERED BY AN ELECTRIC OR DIESEL ENGINE.

AMONG THE SMALLEST DIMENSIONS

- Narrow and exceptionally low shape of the tub

- Facilitated passage even in the narrowest spaces

- RICH STANDARD EQUIPMENT

- Independent plumbing system

- Electronic weighing system

- Mechanical parking brake

- Precise and uniform discharge

- Counterknives for quickly chopping fodder

- ENAMA approved – N° 21-006

STANDARD EQUIPMENT MONO ST

- Predisposition for left side discharge

- Adjustable towing drawbar

- Teleflexible controls

- Mechanical parking brake

- Complete plumbing system

- Cardano

- Mechanical support foot

- Weighing with non-programmable indicator

STANDARD EQUIPMENT MONO ST PLUS

- Predisposition for left side discharge

- Auger reverser

- Adjustable towing drawbar

- Teleflexible controls

- Mechanical parking brake

- Complete plumbing system

- Cardano

- Mechanical support foot

- Weighing with non-programmable indicator

DOUBLE FLOW SYSTEM

AN ORIGINAL AND UNREPEATABLE PATENTED SYSTEM

This advanced cutting and mixing system, with a single large horizontal auger, ensures extreme operational reliability and one of the smallest machine dimensions on the market. The presence of a single rotating element and the elimination of gears and chains eliminate the risk of sudden breakages, also limiting the power absorbed. All this translates into fuel savings, lower maintenance costs and less expenses for spare parts.

AMONG THE SMALLEST DIMENSIONS

The narrow and exceptionally low shape of the tub facilitates passage even in the narrowest spaces. In summary:

- OPTIMIZATION OF THE QUALITY OF THE FINAL PRODUCT

- EXTREME OPERATIONAL RELIABILITY

- CONSISTENT COSTS REDUCTION

- MAXIMUM PROFITABILITY

MIXING: HOW IT WORKS

TWIN FLOW SYSTEM

The single auger with opposing spirals, working in the special mixing tank with differentiated volumes, imposes a double dynamic flow on the materials (Twin flow) from the front and rear parts towards the center of the tank.

LARGE SPIRALS EQUIPPED WITH KNIVES

Designed exclusively by Sgariboldi, they ensure movement in two rotary flows. This double flow facilitates the forage to come together in a single process, guaranteeing unparalleled cutting capacity and effectiveness and a mixing homogeneity that is clearly above average.

REDUCED MIXING TIMES

Inside the tank, a distribution arm, the so-called deflector, allows a correct flow of materials, reducing mixing times and eliminating stagnation points, common to many multi-auger machines.

Viale Pietro Nenni, 15, 26845 Codogno LO, Italia