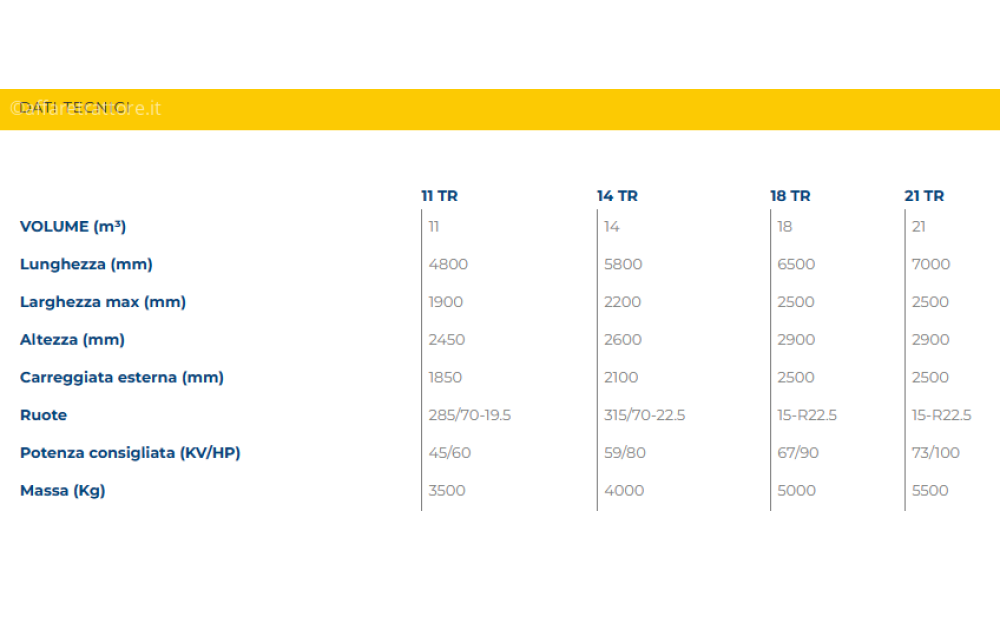

TRAILED WITH BLADE IMPELLER – FROM 11 TO 21 M³

Equipped with Gulliver technology with blade impeller, the Gulliver trailed mixer stands out for a very high level mix and large volumes

ALSO AVAILABLE IN STATIONARY VERSION WITH ELECTRIC OR DIESEL ENGINE

MIXED WITHOUT EQUAL

- The paddle impeller delicately treats each ingredient, respecting its constituent structure

- The mixture is soft and homogeneous, certified by authoritative international institutes

- The tests conducted demonstrate that it is also perfectly suitable for the preparation of compound and integrated compound feed

TOP LEVEL COMPONENTS

- Reliability

- Durability over time

AT THE TOP OF THE RANGE

- Optimal use of the tank's capacity

- Structure and tank in high thickness steel

- Weighing system with single setting indicator

STANDARD EQUIPMENT

- Mixing system with large single impeller and horizontal cylindrical tank

- Optimal use of the tank's capacity

- Structure and tank in high thickness steel

- Adjustable towing drawbar

- Door activation and drainage from hydraulic sockets on the tractor using quick couplings (capacity 20 lt – 140 Bar)

- Weighing system with single setting indicator

- Complete hydraulic system. Mechanical parking brake

- Mechanical support foot

- Gearbox for double speed auger rotation

- Remote control with teleflex for speed change

GULLIVER TECHNOLOGY

PADDLE MIXING SYSTEM

Designed to safeguard the structure of foods as much as possible, it treats each raw material according to its constituent structure and mixes it as best as possible, completely eliminating friction in every mixing phase.

A CALIBRATED CUT ON THE INGREDIENTS

Everything in the Gulliver is designed for optimal mixing; all the products flow uniformly into the tank

and are treated delicately and effectively while preserving their structure.

REDUCED WORKING TIMES

This innovative system separates the cutting and mixing phases, respecting the structure of each individual ingredient. The work action translates into:

- MORE PRECISION

- MORE DELICACY

- REDUCED TIMES

- LESS CONSUMPTION

- CNR CERTIFIED MACHINES

Thanks to its revolutionary technology, it can boast - UNIQUE IN ITALY - the certification of mixing quality by the CNR (National Research Council).

The tests conducted certify that Gulliver is also suitable for the preparation of compound and integrated compound feed.

In 2004 Gulliver obtained the international Inel d'Or award given by the authoritative Eleveur Laitier, as a technical innovation for the livestock farming machinery category.

In 2005 it won the award given by the DLZ Group as a technical innovation for cattle feeding technology.

HOW DOES IT WORK:

-FIRST SIZE

MILLING SYSTEM: EXCELLENT PERFORMANCE EVEN ON THE MOST DIFFICULT PRODUCTS

The cutting system is customized: six types of cutter knives respond to every specific cutting need.

MILL: MAXIMUM CUTTING PRECISION

Gulliver technology reaches its maximum performance with the use of the mill, a technology that can be inserted and disengaged according to cutting needs and specifically developed to act best on the structure of each individual component.

Long fiber fodder is cut by the cutter/mill combination during loading, ingredients that do not require cutting are instead conveyed directly into the bowl

of mixing without passing through the mill.

The operator can choose either to vary the cutting length or not to cut at all, thus having total control over the ration.

-THEN MIX

PROGRAMMED AND PRE-ORDERED FLOWS

The bowl is loaded uniformly thanks to the loading system which modulates the launch of the products from the conveyor, while the impeller delicately mixes the different ingredients.

The result is a total absence of friction in every mixing phase as well as the total emptying of the tank during the unloading phase.

Viale Pietro Nenni, 15, 26845 Codogno LO, Italia