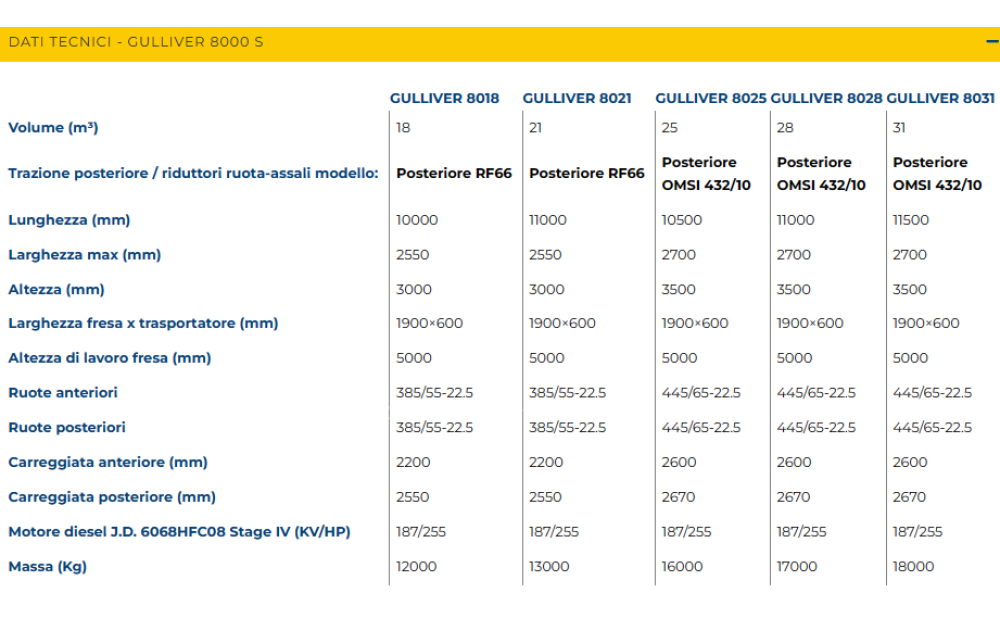

SELF-PROPELLED WITH BLADE IMPELLER – FROM 18 TO 31 M³

Equipped with horizontal blade technology and specifically designed to obtain optimal mixing, Gulliver 8000 S stands out for its high level performance and large volumes.

ALSO AVAILABLE IN THE VERSION WITHOUT MILLING UNIT

- New and renewed design, for a satisfying experience not only from the performance side; so that even the aesthetic component is able to convey a message of value

- Further improved hydraulic system, which limits dispersions and guarantees greater power availability and lower consumption, as well as very high levels of efficiency

- Enhanced software: created together with I-Cab 2 and then transferred to Renesis II, it allows total interaction with the machine for even greater assistance to the operator and even higher control standards.

- Improved load capacity thanks to excellent weight distribution

- Better cooling of the engine compartment thanks to the new rear bonnet

SOLID AND RELIABLE

- Highly resistant modular frame and top-level components ensure reliability and durability over time

- Fully opening rear bonnet which allows complete accessibility to the diesel engine and hydrostatic systems

AT THE TOP OF THE RANGE

- John Deere 6-cylinder Stage V engine

- Automatic transmission

- Rear-wheel drive or 4-wheel drive

- 2 or 4 steering wheels

- Hydraulic suspensions with self-leveling system (optional)

- Tank cover useful for considerably reducing the dust generated by the mixing system (optional)

STANDARD EQUIPMENT

- Low left door with chain unloading

- Conveyor with stainless steel bottom and sides

- Double speed conveyor

- Double impeller speed

- Heating and ventilation system

- Exhaust speed regulator in the cabin

- Weighing with programmable indicator

- Reversible fan

- FLEXXAIR diesel engine radiator

- Air conditioning system

- Grammer Maximo Comfort pneumatic seat with heating

- 600 mm mill on the conveyor

- Traction with automatic engines – (0-20 km/h)

- Cab right side wiper

- Camera system (rear camera integrated into the display)

- Renesis II cabin

GULLIVER TECHNOLOGY

PADDLE MIXING SYSTEM

Designed to safeguard the structure of foods as much as possible, it treats each raw material according to its constituent structure and mixes it as best as possible, completely eliminating friction in every mixing phase.

A CALIBRATED CUT ON THE INGREDIENTS

Everything in the Gulliver is designed for optimal mixing; in the tank all the products flow uniformly and are treated delicately and effectively, preserving their structure.

REDUCED WORKING TIMES

This innovative system separates the cutting and mixing phases, respecting the structure of each individual ingredient. The work action translates into:

- MORE PRECISION

- MORE DELICACY

- REDUCED TIMES

- LESS CONSUMPTION

- CNR CERTIFIED MACHINES

Thanks to its revolutionary technology, it can boast - UNIQUE IN ITALY - the certification of mixing quality by the CNR (National Research Council).

The tests conducted certify that Gulliver is also suitable for the preparation of compound feed and integrated compounds.

In 2004 Gulliver obtained the international Inel d'Or award given by the authoritative Eleveur Laitier, as a technical innovation for the livestock farming machinery category.

In 2005 it won the award given by the DLZ Group as a technical innovation for cattle feeding technology.

HOW DOES IT WORK:

- FIRST SIZE

MILLING SYSTEM: EXCELLENT PERFORMANCE EVEN ON THE MOST DIFFICULT PRODUCTS

The cutting system is customized: six types of cutter knives respond to every specific cutting need.

MILL: MAXIMUM CUTTING PRECISION

Gulliver technology reaches its maximum performance with the use of the mill, a technology that can be inserted and disengaged according to cutting needs and specifically developed to act best on the structure of each individual component.

Long fiber fodder is cut by the cutter/mill combination during loading, ingredients that do not require cutting are instead conveyed directly into the bowl

of mixing without passing through the mill.

The operator can choose either to vary the cutting length or not to cut at all, thus having total control over the ration.

- THEN MIX

PLANNED AND PRE-ORDERED FLOWS

The bowl is loaded uniformly thanks to the loading system which modulates the launch of the products from the conveyor, while the impeller delicately mixes the different ingredients.

The result is a total absence of friction in every mixing phase as well as the total emptying of the tank during the unloading phase.

Viale Pietro Nenni, 15, 26845 Codogno LO, Italia