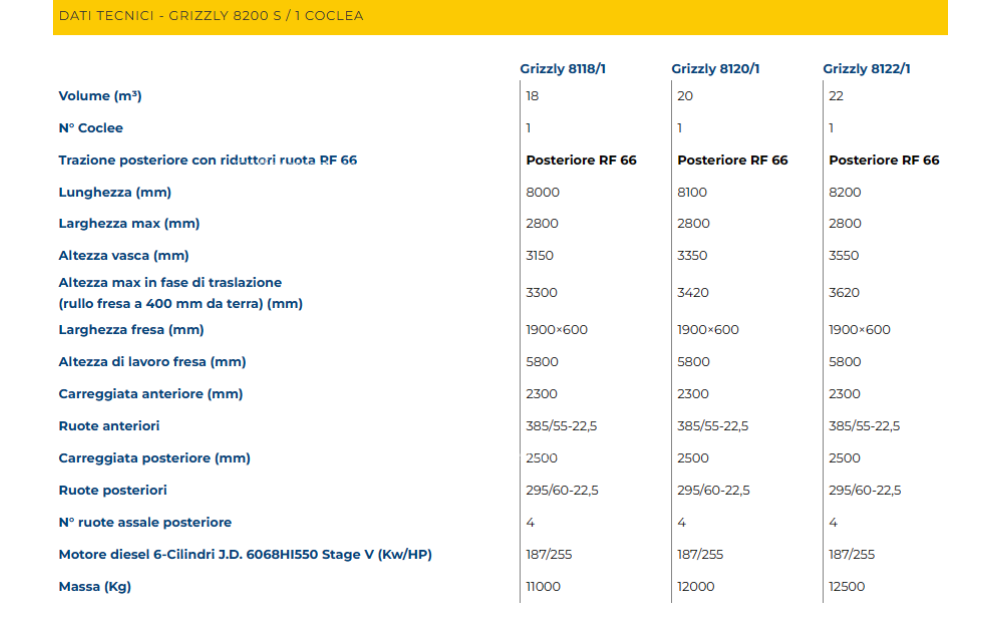

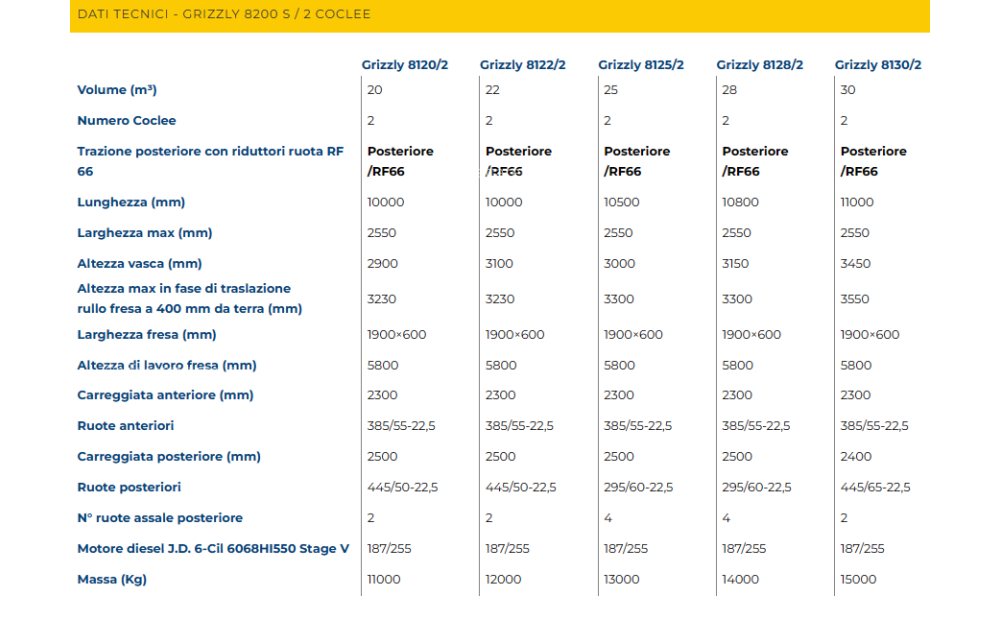

SELF-PROPELLED VERTICAL SINGLE OR TWO AUGER FROM 18 TO 30 M³

Equipped with a vertical mixing system with one or two augers, and specifically designed to obtain high productivity, Grizzly 8100 S stands out for its very high level performance and large volumes, which allow it to establish itself as the best performing self-propelled machine available on the market.

AVAILABLE ON REQUEST IN THE VERSION WITHOUT MILLING APPARATUS

- New and renewed design, for a satisfying experience not only from the performance side; because even the aesthetic component conveys a message of value

- Further improved hydraulic system, which limits dispersions and guarantees greater power availability and lower consumption, as well as very high levels of efficiency

- Enhanced software: created together with I-Cab 2 and then transferred to Renesis II, it allows total interaction with the machine for even greater assistance to the operator and even higher control standards

- Improved load capacity thanks to excellent weight distribution

- Better cooling of the engine compartment thanks to the new rear bonnet

SOLID AND RELIABLE

- Highly resistant modular frame and top-level components ensure reliability and durability over time

- Fully opening rear bonnet which allows total accessibility to the diesel engine and hydrostatic systems

AT THE TOP OF THE RANGE

- John Deere 6-cylinder Stage V engine

- Automatic transmission

- Rear-wheel drive or 4-wheel drive

- 2 or 4 steering wheels

- Hydraulic suspensions with self-leveling system (optional)

- Tank cover useful for considerably reducing the dust generated by the mixing system (optional)

STANDARD EQUIPMENT

-Standard chain bilateral front exhaust carpet

- N° 2 auger speeds

- Double speed conveyor

- Conveyor with bottom and lower sides of the cutter in stainless steel

- Heating and ventilation system

- Exhaust speed regulator in the cabin

- Fodder containment ring

- Weighing system with programmable indicator

- FLEXXAIR reversible diesel engine radiator fan

- Air conditioning system

- Grammer Maximo Comfort pneumatic seat with heating

- Traction with automatic engines – (0-20 km/h)

- N° 2 hydraulic contrasts

- Cab right side wiper

- Camera system (rear camera integrated into the display)

- Renesis II cabin

- Drain with chain and stainless steel bottom

VS.2 technology

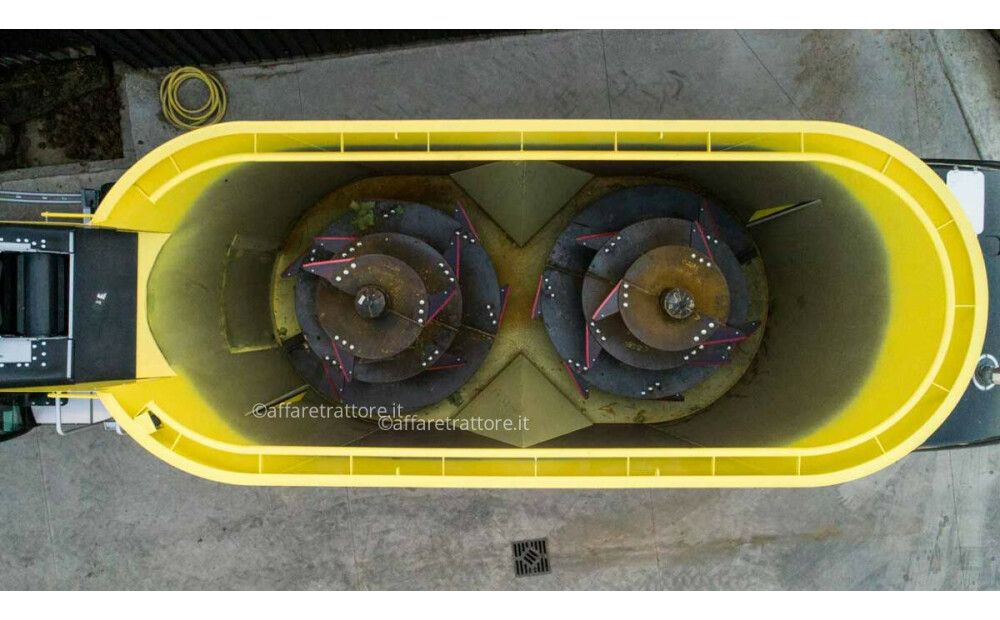

VERTICAL MIXING SYSTEM

SIMPLE CONSTRUCTION AND COMPACT DIMENSIONS

Over the years, Sgariboldi has reached the highest level in vertical mixing, ideal for the rapid splitting of fodder bales of any shape, weight and size. High thickness frame, bottom and walls of the tank characterize the series. Machines designed for high productivity, adaptable to any work requirement.

VERSATILE, FUNCTIONAL AND RELIABLE MACHINES

The shape of the tank conditions the flow of materials in order to quickly obtain an optimal mix, preserving the structure of the various ingredients. The delicate treatment of the products ensures the maintenance of an excellent "fodder value" of the silage and prevents heating of the final product. The careful study and first-rate components allow maximum performance with reduced power absorption and notable energy savings, guaranteeing:

- WORKING COMFORT

- FAST TIMES

- SAFEGUARDING THE STRUCTURE OF THE PRODUCTS

- HOW DOES IT WORK

MIXING

AUGER AND KNIVES FOR MAXIMUM CUTTING EFFICIENCY

The conical auger, combined with the special knives allows:

- cutting long fiber products

- the rapid splitting of the round bales

- very short working times avoiding heating of the final product

- the maintenance of excellent forage value and extraordinary softness of the ration

QUICK MIXING, QUALITY MIXING

- Once the last ingredient has been loaded, the combined action of the bowl, auger and contrasts allows you to quickly obtain a soft, homogeneous and perfectly cut mixture.

- Great respect for the structure of the silage

- At all times during mixing the product is never pressed against the walls

- Increase in the cattle's appetite and speed of transit in the rumen

Viale Pietro Nenni, 15, 26845 Codogno LO, Italia