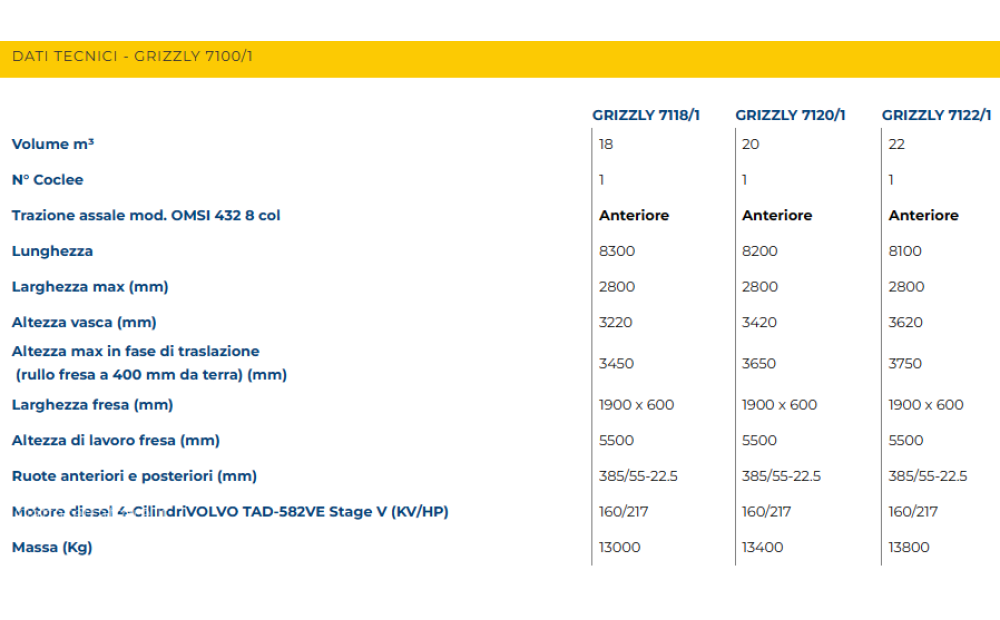

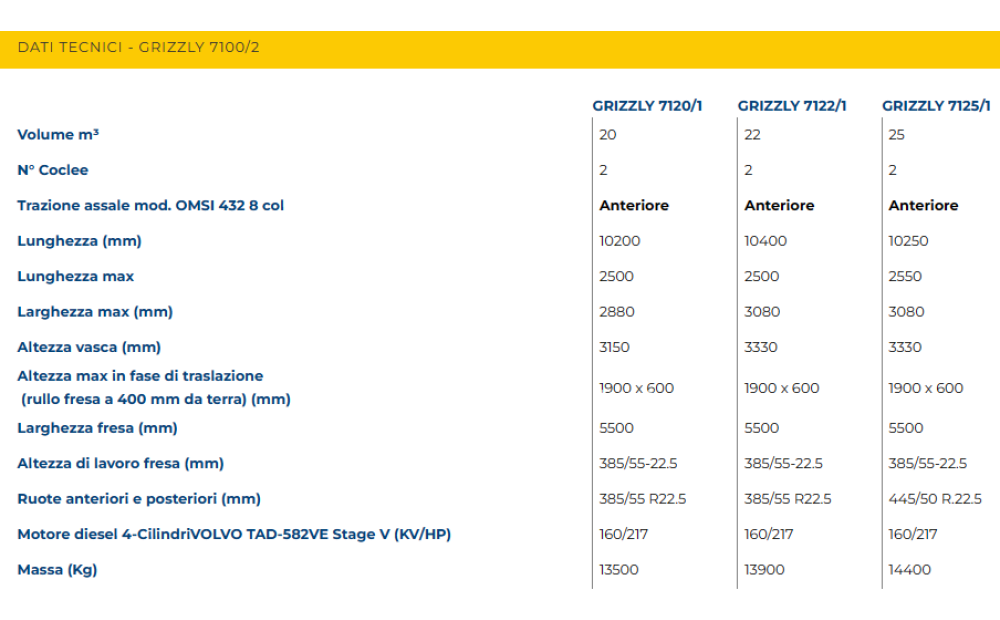

Equipped with vertical technology with one or two augers, the GRIZZLY 7100 returns to the market in a new and improved version, perfect to meet the needs of farmers who need a compact machine capable of great performance.

COMPACT AND PERFORMING

Characterized as an intermediate solution between 6000 and 8000, the 7000 series is the result of careful design which, accompanied by first-rate components, allows maximum performance with reduced power absorption, notable energy savings and maximum agility thanks to the dimensions contained.

CHARACTERISTICS OF THE SERIES

- The 218 hp VOLVO 4-cylinder STAGE V engine is placed transversally between the cab and the tank in order to offer an excellent working view and ideal weight distribution

- The FAN DRIVE fan, an intelligent device that electronically controls the cooling needs of the diesel engine, allows significant fuel savings and a notable reduction in noise

- The hydraulic oil exchanger integrated into the diesel engine radiator allows for less maintenance and greater reliability

- The limited-slip front axle allows a steering angle of almost 40 degrees, ensuring great maneuverability which can be further increased by the 4-wheel steering (optional)

The 4-wheel drive version is also available as an option

STANDARD EQUIPMENT

- Reversible Fan Drive diesel engine water radiator fan

- Front left side chain discharge belt

- Conveyor with bottom and sides in stainless steel

- Heating and ventilation system

- Exhaust speed regulator in the cabin

- N° 2 auger speeds

- Double speed conveyor

- Fodder containment ring

- Weighing with programmable indicator

- Traction with automatic engine (0-25 km/h)

- Reinforced chassis with transverse engine between body and cab

- Limited-slip automatic differential

- N° 2 hydraulic contrasts

- Grammer Maximo Comfort heated pneumatic seat

- Cab right side wiper

- Camera system (rear camera integrated into the display)

- Renesis II cabin

VS.2 technology

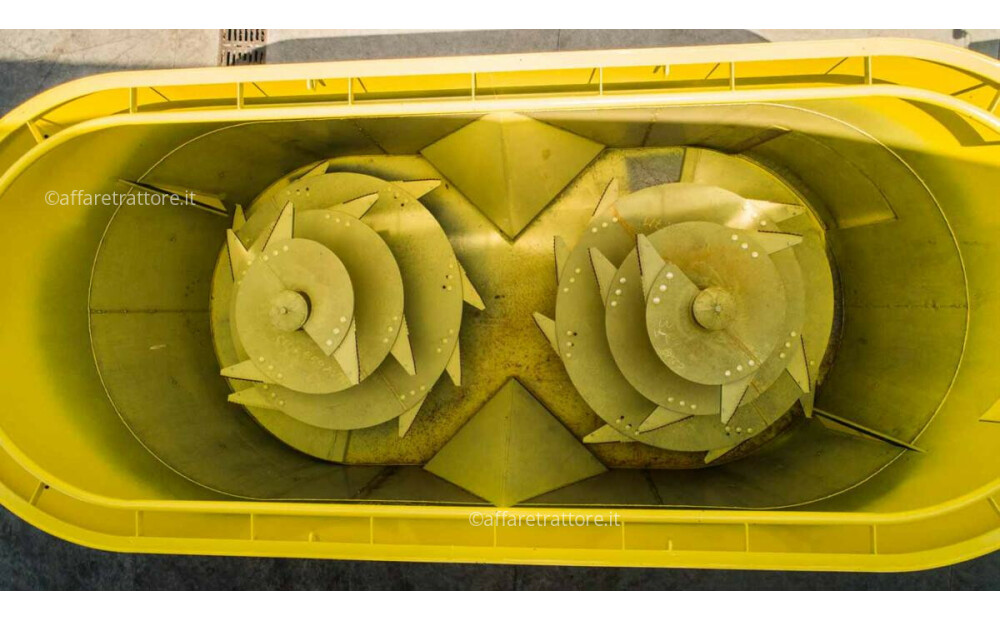

VERTICAL MIXING SYSTEM

SIMPLE CONSTRUCTION AND COMPACT DIMENSIONS

Over the years, Sgariboldi has reached the highest level in vertical mixing, ideal for the rapid splitting of fodder bales of any shape, weight and size. High thickness frame, bottom and walls of the tank characterize the series. Machines designed for high productivity, adaptable to any work requirement.

VERSATILE, FUNCTIONAL AND RELIABLE MACHINES

The shape of the tank conditions the flow of materials in order to quickly obtain an optimal mix, preserving the structure of the various ingredients. The delicate treatment of the products ensures the maintenance of an excellent "fodder value" of the silage and prevents heating of the final product. The careful study and first-rate components allow maximum performance with reduced power absorption and notable energy savings, guaranteeing:

- WORKING COMFORT

- FAST TIMES

- SAFEGUARDING THE STRUCTURE OF THE PRODUCTS

- HOW DOES IT WORK

MIXING

AUGER AND KNIVES FOR MAXIMUM CUTTING EFFICIENCY

The conical auger, combined with the special knives allows:

- cutting long fiber products

- the rapid splitting of the round bales

- very short working times avoiding heating of the final product

- the maintenance of excellent forage value and extraordinary softness of the ration

QUICK MIXING, QUALITY MIXING

- Once the last ingredient has been loaded, the combined action of the bowl, auger and contrasts allows you to quickly obtain a soft, homogeneous and perfectly cut mixture.

- Great respect for the structure of the silage

- At all times during mixing the product is never pressed against the walls

- Increase in the cattle's appetite and speed of transit in the rumen

Viale Pietro Nenni, 15, 26845 Codogno LO, Italia