VERTICAL TOWED WITH ONE OR TWO AUGERS

Available in volumes from 8 to 19 m3, Florida is an innovative vertical cutter-mixer, simple and within everyone's reach. Extreme construction simplicity and very compact dimensions make it an optimal solution for small and medium-sized businesses. The special conical auger, the result of specific studies, combined with the shape of the bowl and the special toothed saber knives, optimizes the cutting of fibrous products.

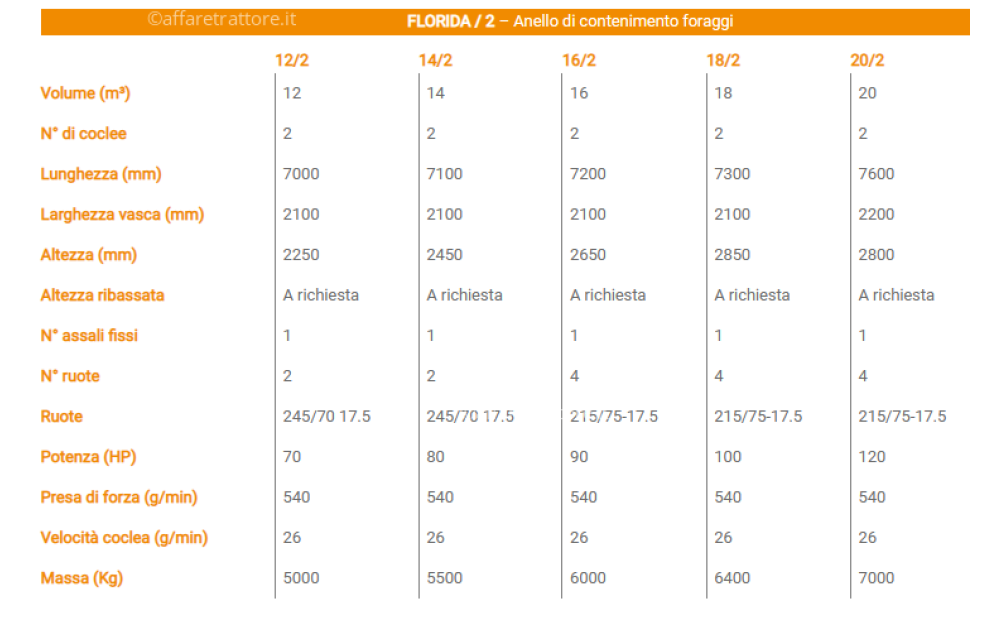

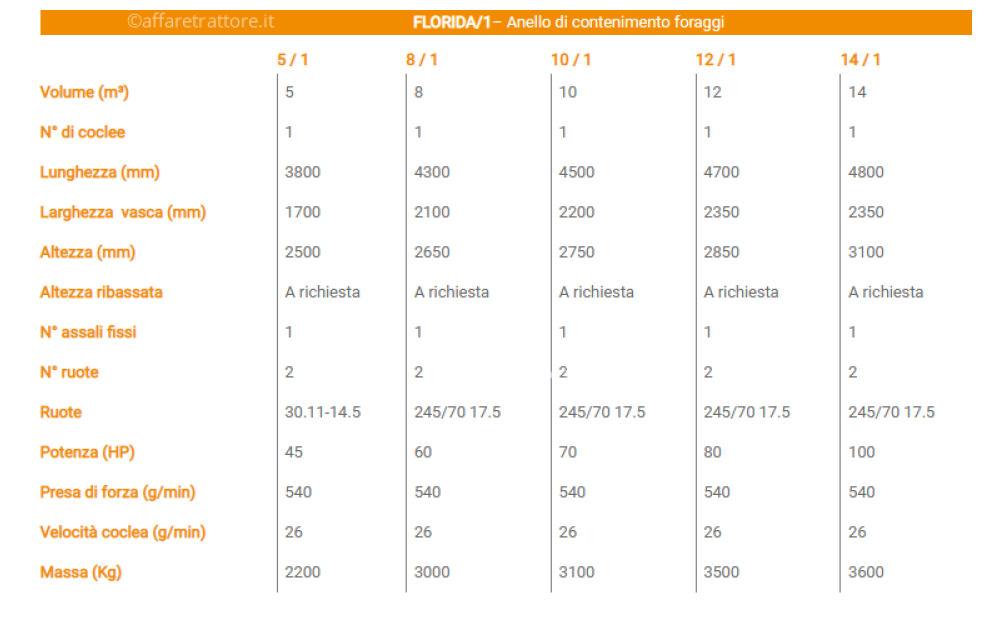

Available in two versions:

• Florida / A with forage containment ring

• Florida / S with conical forage containment overbank

STANDARD EQUIPMENT

- One and two vertical augers

- Adjustable towing drawbar

- Direct exhaust with right side front door

- Industrial planetary gearbox

- Augers at one rotation speed

- Door activation by hydraulic grip on the tractor - quick couplings (capacity 30 l - 140 Bar)

- Mechanical support foot

- N° 2 manual tackles

- PERIN weighing system with non-programmable indicator

- Standard cardan

ALSO AVAILABLE IN STATIONARY VERSION, WITH ELECTRIC OR DIESEL ENGINE.

VERTICAL MIXING SYSTEM

VERSATILITY AND EFFICIENCY

Omas cutter-mixers are machines characterized by extreme simplicity of use and maintenance. The shape of the mixing tank conditions the flow of materials in order to quickly obtain an optimal mix, guaranteeing the clean cut of the products and preserving the structure of the ingredients.

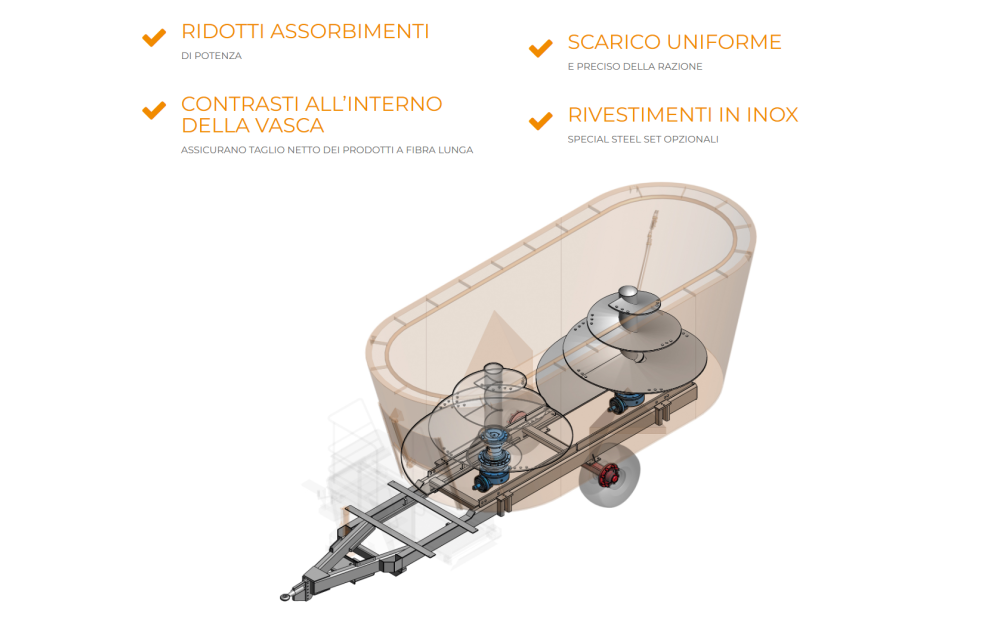

ADVANTAGES AND QUICK MIXING

The vertical system has the advantage of achieving rapid cutting and mixing, even with large round or rectangular bales, which can be loaded without the pre-shredding process. The mixing of the loaded ingredients is fast and homogeneous and considers hay as the first ingredient. The mixed products are distributed in the feeder effectively and quickly, so as to keep all the organoleptic characteristics of the products unchanged.

HOW DOES IT WORK:

MIXING AUGER AND KNIVES FOR MAXIMUM CUTTING EFFICIENCY

The conical auger combined with the special toothed knives optimizes the cutting of long fiber products. The delicate treatment of the products ensures the maintenance of an excellent "fodder value" of the silage and prevents overheating of the final product. The careful study and first-rate components allow maximum performance with reduced power absorption and notable energy savings, guaranteeing:

- Convenience of work

- Fast times

- Safeguarding the structure of the products

Viale Pietro Nenni, 15, 26845 Codogno LO, Italia